Experienced ground improvement specialist

Menard brings over 30 years of experience in the design and build of specialist ground improvement solutions in the UK.

We offer a broad range of ground improvement techniques and combined with innovative designs we can provide practical and sustainable solutions which are more cost effective than traditional piles. We pride ourselves on being able to deliver solutions for a wide range of soil conditions and to provide a seamless service between initial contact and delivery on site.

Experienced ground improvement specialist

Menard brings over 30 years of experience in the design and build of specialist ground improvement solutions in the UK.

We offer a broad range of ground improvement techniques and combined with innovative designs we can provide practical and sustainable solutions which are more cost effective than traditional piles. We pride ourselves in being able to deliver solutions for a wide range of soil conditions and provide a seamless service between initial contact and delivery on site.

Techniques

Menard delivers the full range of ground improvement techniques to provide effective, innovative and economical solutions for its clients.

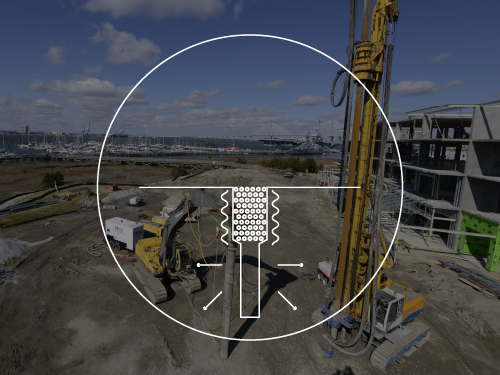

Controlled Modulus Columns (CMC)

Where traditional ground improvement techniques may not be suitable, Controlled Modulus Column rigid inclusions (CMCs) provide a fast and economical ground improvement alternative to piling.

Vibro Stone Columns

Vibro Stone Columns are installed into soft to firm cohesive or loose to medium dense granular natural soils or made ground.

Bi-Modulus Columns

Where CMCs are adopted on sites with near surface granular or mixed soils, the top of the CMC can be replaced with stone aggregate to produce a composite column, known as a Bi-Modulus Column (BMC).

Vibrocompaction

Where sites are underlain by sands and gravels, Vibrocompaction uses our vibrating poker technology to improve the density of these soils commonly on reclaimed land areas.

Dynamic Compaction

Large sites underlain by loose materials can be effectively treated using our Dynamic Compaction, a ground improvement technique that densifies the soil to reduce ground void spaces improving the soil capacity.

Dynamic Replacement

Dynamic Replacement is an adaptation of the Dynamic Compaction process for organic, saturated or weak cohesive soils.

Rapid Impact Compaction (RIC)

The compaction of near surface granular or mixed soils, can be achieved by the introduction of high frequency energy impacts, using our Rapid Impact Compaction technique (RIC).

Vertical Drains and Vacuum Consolidation

Vertical Drains, also known as Prefabricated Vertical Drains or Wick Drains, are made up of a plastic core surrounded by a geotextile that acts as a filter, provide an economical way to accelerate consolidation in saturated soils.

Sectors

Our teams design and build ground improvement solutions for all types of buildings, ports, airports, highways, railways, buildings, process and energy infrastructure projects.

Ports & Airports

Port and airport infrastructures are frequently built upon alluvial plains and coastlines. Sites often consist of compressible soils which are saturated, and require ground treatment to accelerate consolidation.

Rail & Road

Menard can provide a range of solutions to meet the varied geotechnical conditions often encountered within the rail & road sector, in order to ensure its long-term reliability.

Process & Energy

The support systems required for energy schemes such as oil, gas, nuclear, windfarm projects are often complex. The most cost-effective foundation solutions often require a combination of ground improvement techniques.

Sectors & Techniques

Menard delivers the full range of ground improvement techniques to provide effective, innovative and economical solutions for its clients. Our teams design, build and refurbish all types of ports, airports, highways, railways, buildings, process and energy infrastructure.

Buckton Fields Primary School, Northampton

OWNER: Portakabin ENGINEER: Structa LLP GENERAL CONTRACTOR: Kenward Construction MAIN FIGURES: 150 Vibro Stone Columns Project Details Due to slab problem on the current Buckton Fields School, Portakabin and Kenward Construction approached Menard UK for a fast solution to build a new Portakabin school of a total floor [...]

Bradford, Seabrook Crisps

OWNER: Calbee Group ENGINEER: TD Jagger Ltd GENERAL CONTRACTOR: TD Jagger Ltd MAIN FIGURES: 642 Controlled Modulus Columns Project Details T D Jagger approached Menard UK to carry out Ground Improvement works beneath the foundations and floor slab of the new Seabrook Crisp factory extension. Controlled Modulus Columns [...]

Kidderminster, Stourport Road

OWNER: Kidderminster College ENGINEER: Central Design Consultants Ltd GENERAL CONTRACTOR: Interclass PLC MAIN FIGURES: 482 Vibro Stone Columns Project Details Interclass Plc approached Menard for a Vibro Stone Column (VSC) quotation, and the works were subsequently awarded as a result of competitive tendering. The scheme is for a [...]

Bolton, Makkah Mosque

OWNER: Makkah Mosque and Muslim Community Centre ENGINEER: SWF Consulting Ltd GENERAL CONTRACTOR: Fox Developments MAIN FIGURES: 707 Vibro Stone Columns Project Details SWF Consulting Ltd were in discussions with us in the initial stages of the design with a view to value engineer the foundation solution for [...]

Uttoexeter Gateway

OWNER: PMW Property ENGINEER: Tunstall King Smith GENERAL CONTRACTOR: X-Cel Construct Limited MAIN FIGURES: 2,084 Controlled Modulus Columns Project Details X-Cel Construct Limited approached Menard to find a cost-effective foundation solution as an alternative to the base pile solution initially proposed. At present one new industrial unit measuring [...]

New Horizon Development – Nottingham

OWNER: Henry Boot Development ENGINEER: BWB GENERAL CONTRACTOR: Bowmer & Kirkland Limited MAIN FIGURES: 1,293 Dynamic Replacement Pillars 38,620 m2 Dynamic Compaction 8,589 Controlled Modulus Columns Project Details The project consisted of the construction of 5 new commercial units and associated service yards and access roads on the [...]

Red Lion Road, Tolworth

OWNER: Chancerygate and Bridges Fund Management ENGINEER: I & L Consulting Limited GENERAL CONTRACTOR: Harmonix Construction MAIN FIGURES: 739 Controlled Modulus Columns 384 Vibro Stone Columns Project Details It was proposed to construct a large industrial development (Units 1-9) at a site off Red Lion Road in Tolworth, [...]

The Steel Works, 105 Culvert Road

OWNER: Avanton Limited ENGINEER: BW Murray GENERAL CONTRACTOR: GS8 Construction MAIN FIGURES: 442 Controlled Modulus Columns Project Details BW Murray approached Menard UK to find a cost-effective alternative foundation solution for the redevelopment of the industrial complex Culvert Court in Battersea, London, with the construction of 3 separate [...]

Momentum London, Rainham

OWNER: Henry Boot Development (HBD) ENGINEER: BWB Consulting GENERAL CONTRACTOR: Readie Construction MAIN FIGURES: 7,598 Controlled Modulus Columns Project Details Readie Construction Limited approached Menard UK to carry out ground improvement in the form of CMC's under 3 new commercial units and adjoining ancillary structures. The project, which [...]

Stoke-on-Trent, Haywood Hospital

OWNER: Midlands Partnership NHS Foundation Trust (MPFT) ENGINEER: Couch Consulting Engineers GENERAL CONTRACTOR: Key Construction (Birmingham, GB) MAIN FIGURES: c.750 Vibro Stone Columns Project Details Haywood Hospital operated by the Midlands Partnership NHS Foundation Trust (MPFT) were replacing the existing outpatients building because the building contained Reinforced Autoclaved [...]

Bloom, 146-156 Brixton Hill, London

OWNER: Bloom Developments ENGINEER: Burrows Graham GENERAL CONTRACTOR: MCS Group MAIN FIGURES: 503 Controlled Modulus Columns Project Details MCS approached Menard UK to find a cost-effective alternative foundation solution for a development by Bloom of two industrial ultra-urban units totalling around 1,600 m² of ground floor in a [...]

Wichelstowe Care Home, Swindon

OWNER: Berkley Care ENGINEER: Ward Associates Consulting Engineers GENERAL CONTRACTOR: Lawrence Baker MAIN FIGURES: 433 Vibro Stone Columns Project Details Following successful collaboration on previous projects, Lawrence Baker approached Menard UK to find a cost-effective alternative foundation solution for the construction of a new care home in Wichelstowe, [...]

CTRL 310 London

Project Details Part of the Channel Tunnel Rail Link (CTRL) is built on Controlled Modulus Columns. Menard suggested this technique to improve the soil along the Thames River in the suburbs of London so that the Eurostar could operate as intended. For this project, Menard used a short mast for the installation of the column [...]

Dockley Road Residential Development, London

OWNER: Matching Green ENGINEER: Terrell GENERAL CONTRACTOR: Legendre MAIN FIGURES: 920 Controlled Modulus Columns (CMC) installed, totalling 3,500 sq/metres Project Details In order to find a cost-effective foundation solution for a new residential development in South East London as an alternative to the base solution of CFA piles [...]

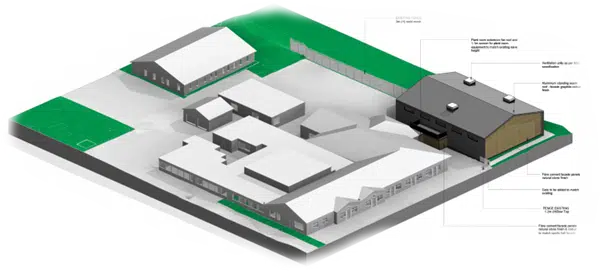

Sky Studios at Elstree

OWNER: Sky ENGINEER: Fairhurst GENERAL CONTRACTOR: BAM MAIN FIGURES: 5,176 Vibro Stone Columns (VSC) installed Project Details This development by Legal & General, Sky and NBCUniversal intends to create the most sustainable film and TV studio in the world. It will comprise 12 sound stages split across 8 [...]

Project Gazelle, Ocado, Bicester

OWNER: Ocado ENGINEER: EirEng GENERAL CONTRACTOR: Glencar Construction MAIN FIGURES: 606 Controlled Modulus Columns (CMC) installed Project Details Glencar Construction approached Menard to find a cost-effective foundation solution for the addition of a mezzanine level required by Ocado inside an existing recently-built warehouse at Symmetry Park in Bicester. [...]

Greenpark Academy, Kings Lynn

OWNER: Norfolk County Council ENGINEER: Concertus GENERAL CONTRACTOR: Cocksedge Building Contractors MAIN FIGURES: 454 Bi-Modulus Columns installed Project Details A new primary school and nursery was to be built in King's Lynn by Norfolk County Council to replace St Edmund's Academy, located two miles from the new site. [...]

Clophill Quarry Residential Development, Bedford

OWNER: Heyfield ENGINEER: NHBC GENERAL CONTRACTOR: Heyfield MAIN FIGURES: 26,550 sq/metres Dynamic Compaction (DC) Project Details Menard completed Dynamic Compaction works beneath the roads (8810m2), 50 housing plots (3700m2) and their gardens (14040m2) for a new residential development in Shefford Road, Clophill Quarry, Bedford. The DC solution provides [...]

North Kyle Wind Farm

OWNER: Brockwell Energy ENGINEER: Tony Gee GENERAL CONTRACTOR: JONES BROS INC MAIN FIGURES: CMCs and DC to a series of 21.5 m/22.2 m diameter gravity bases Project Details Menard was initially approached by a design consultancy, Tony Gee, to assist in developing a ground improvement solution which would [...]

Bedworth Leisure Centre

OWNER: Nuneaton & Bedworth Borough Council ENGINEER: Hexa Consulting GENERAL CONTRACTOR: BAM Construction (Solihull, GB) MAIN FIGURES: 800 CMCs Project Details Nuneaton & Bedworth Borough Council required the existing outdated 1970's leisure centre to be replaced with a new Physical Activity Hub, and procured BAM as the main [...]

Market Drayton, New Care Home

OWNER: Lovett Care Limited ENGINEER: Dudleys Consulting Engineers GENERAL CONTRACTOR: Torsion Projects MAIN FIGURES: c.480 Vibro Stone Columns Project Details A new residential care home was proposed to be constructed at a site with a shallow groundwater table and running sands. The proposed 3-storey structure was to be [...]

Grange over Sands, Station Square

OWNER: James Hall ENGINEER: Sleater & Watson GENERAL CONTRACTOR: RH Irving Construction Limited MAIN FIGURES: 340 Controlled Modulus Columns 232 Bi-Modulus Columns Project Details Menard was engaged early in the project through initial discussions with the Structural Engineer, who was seeking a suitable ground improvement solution for the [...]

Failsworth, Daisy Nook Farm

OWNER: Mr & Mrs Clegg ENGINEER: Springett Associates GENERAL CONTRACTOR: SGD Building Ltd. MAIN FIGURES: 53 Vibro Stone Columns Project Details The owners of a single dwelling initially intended to renovate the existing structure. However, following a detailed assessment, it became evident that the building was largely beyond [...]

St Helens, Florida Farm

OWNER: Panattoni ENGINEER: Burrows Graham GENERAL CONTRACTOR: TanRo MAIN FIGURES: c.1,000 Controlled Modulus Columns Project Details Menard was initially approached by TanRo to provide a ground improvement solution for a new industrial unit planned on a site previously used as arable farmland. The proposed development featured a large [...]

Doncaster, Premier Park

OWNER: Base Build Services Ltd ENGINEER: Baynham Meikle GENERAL CONTRACTOR: Base Build Services Ltd MAIN FIGURES: c.1,150 Controlled Modulus Columns & c.1,600 Vibro Stone Columns Project Details Menard was invited to provide a quotation for ground improvement works for a large industrial facility, following a prior site visit [...]

Kidderminster, Silverwoods Trade Park

OWNER: Omega SB Holdings ENGINEER: PCS Consulting Engineers GENERAL CONTRACTOR: Omega SB Holdings MAIN FIGURES: c.340 Controlled Modulus Columns & c.145 Vibro Stone Columns Project Details Menard was approached to provide a quote for ground improvement to support four small industrial units. This development is adjacent to a [...]

Wesham, Coronation Way

OWNER: HTI Group ENGINEER: TRP Consulting Engineers GENERAL CONTRACTOR: Portal Construction N.W. Ltd. MAIN FIGURES: c.2,800 Controlled Modulus Columns Project Details Portal Construction engaged Menard to undertake ground improvement works beneath the new HTI headquarters building in Wesham, utilising Controlled Modulus Columns (CMC) technology. The project was delivered [...]

Woodside Quarry Residential Development, Horsforth

OWNER: Taylor Wimpey ENGINEER: Whitby Bird GENERAL CONTRACTOR: Sirius Group MAIN FIGURES: 8,000 sq/metres Dynamic Replacement (DR) 15,000 sq/metres Dynamic Compaction (DC) Project Details Menard completed Dynamic Compaction/Dynamic Replacement (DC/DR) works beneath 106 housing plots and associated roads, retaining walls and gardens for a new residential development at [...]

Wrexham, Newbridge Road

OWNER: A. N. Richards Ltd. ENGINEER: JPS Structural Chester GENERAL CONTRACTOR: Studio83 MAIN FIGURES: 72 Stone Columns Project Details A new HGV Workshop & MOT Centre is being constructed on a site which has been a HGV haulage yard for the past decade. Menard was initially approached by [...]

Congleton, Viking Way

OWNER: Roe Developments (Chesterfield, GB) ENGINEER: Jackson Purdue Lever GENERAL CONTRACTOR: Roe Developments (Chesterfield, GB) MAIN FIGURES: 130 Stone Columns Project Details The Viking Way area of Congleton has been undergoing substantial development in recent years. This development is part of the broader growth strategy for Congleton, which [...]

Bredbury, Whitefield Road

OWNER: Easy Access Self-Storage Stockport ENGINEER: Brennan Consult GENERAL CONTRACTOR: Williams Build and Design Limited MAIN FIGURES: 388 Controlled Modulus Columns Project Details The Structural Engineer initially approached Menard for a Ground Improvement solution for the proposed extension of a self-storage facility. The proposed extension was to be [...]

Amington Primary School, Tamworth

OWNER: Staffordshire County Council ENGINEER: Hydrock GENERAL CONTRACTOR: G.F. Tomlinson & Sons Ltd. MAIN FIGURES: 300 Controlled Modulus Columns Project Details The development comprises a low-rise primary school, for Staffordshire County Council. GF Tomlinson requested Menard to submit a competitive tender for ground improvement works, as an alternative [...]

Tor View School, Haslingden

OWNER: Tor View School ENGINEER: Booth King Partnership Ltd GENERAL CONTRACTOR: H Cumberbirch & Son Ltd MAIN FIGURES: 114 Stone Columns Project Details Tor View School in Haslingden was extending the school by incorporating a new multi-use space providing sports facilities and a performance hall, as well as [...]

Old Walsall Road, Hamstead, Birmingham

OWNER: Prime Box Ltd ENGINEER: Nolan Associates GENERAL CONTRACTOR: A&H Construction & Developments (Holdings) Ltd MAIN FIGURES: 990 Controlled Modulus Columns Project Details The development comprises three industrial units on a site underlain by a wedge of weak alluvial deposits. Menard was approached in the first instance by [...]

Horwich, Rivington Chase Link Road

OWNER: Bolton Council ENGINEER: E3P + Curtins GENERAL CONTRACTOR: D Morgan PLC MAIN FIGURES: 806 Dynamic Replacement Pillars, 1,615 Controlled Modulus Columns, 146 Vertical Drains Project Details The proposed scheme for Bolton Council involved construction of a new, 1km long link road intended to open up to new [...]

Stretford, The Kellogg’s Building

OWNER: Trafford Council and Bruntwood ENGINEER: SGI Consulting Engineers GENERAL CONTRACTOR: Caddick Construction MAIN FIGURES: 861 Vibro Stone Columns Project Details Caddick Construction approached Menard for a cost effective Ground Improvement solution on this high profile project. It was proposed to construct 2 No. apartment blocks with retail [...]

New Entrance Facility at London Stadium (ex Olympic Stadium)

OWNER: E20 Stadium LLP ENGINEER: JDL Consultants GENERAL CONTRACTOR: Modulek MAIN FIGURES: 44 Controlled Modulus Columns (CMC) installed Project Details Modulek approached Vibro Menard to find an alternative efficient foundation solution for the development of a new entrance facility at the London Stadium (ex Olympic Stadium). This new [...]

Two warehouse units in Altrincham, Manchester

OWNER: Quorum Estates Ltd ENGINEER: Booth King Partnership GENERAL CONTRACTOR: Caddick Construction – North West MAIN FIGURES: 1,160 Controlled Modulus Columns Project Details Menard was contacted at an early stage by the Consulting Engineer Booth King Partnership, to assess the feasibility of a site for a [...]

Units 1,2 and 3 at Hinkley Park, Leiceistershire

OWNER: IM Properties ENGINEER: Fairhurst GENERAL CONTRACTOR: Winvic Construction MAIN FIGURES: 2,114 Dynamic Replacement pillars Project Details Following the successful completion of ground improvement works on the previous phase of this Hinckley Park (Leiceistershire) logistics development in 2019, Winvic approached Menard to find a cost-effective foundation solution for [...]

Multi-use Development at 331 Wick Road, Hackney Wick

OWNER: Bloom Developments ENGINEER: Jackson Purdue Lever GENERAL CONTRACTOR: TanRo MAIN FIGURES: 216 Controlled Modulus Columns Project Details TanRo approached Menard to find a cost-effective alternative foundation solution for a development by Bloom of two industrial units totalling 600 m² of ground floor in a prime location in [...]

Fife Energy from Waste Facility, Westfield

OWNER: Brockwell Energy ENGINEER: Incico GENERAL CONTRACTOR: HZI MAIN FIGURES: 13,282m² Dynamic Compaction Project Details The project consisted in the construction of a new Energy From Waste facility in Fife, Scotland. Menard has been approached by repeat client HZI to design and implement an alternative ground improvement solution [...]

Yeadon Way Railway Embankment, Blackpool

OWNER: Blackpool Borough Council ENGINEER: Coffey Geotechnical Limited GENERAL CONTRACTOR: Galliford Try MAIN FIGURES: 1,500 Controlled Modulus Columns to depths of up to 15m Project Details The main arterial road into Blackpool uses a 30 year old railway embankment which was constructed on soft alluvial soils. The embankment [...]

Aldi Store and Car Park in Kenmare, Republic of Ireland

OWNER: Aldi ENGINEER: Downes Associates GENERAL CONTRACTOR: McDonnel Piling MAIN FIGURES: 912 Vibro Concrete Columns (VCC) with enlarged heads to 8m Project Details MOS Group were contracted to build a new Aldi store and car park. The store and car park were originally designed to be built on [...]

Lidl Regional Distribution Centre, Avonmouth

OWNER: Lidl ENGINEER: Jubb Consulting GENERAL CONTRACTOR: TSL Projects MAIN FIGURES: 5,597 Controlled Modulus Columns, totalling 72,970 linear metres 5,235 Vertical Drains, totalling 68,055 linear metres 6 Stress Load Testing zones and 19 CMC Stress Load Testing zones Project Details The development was for a new regional distribution [...]

Bexhill to Hastings Link Road, East Sussex

OWNER: East Sussex County Council ENGINEER: Mott MacDonald GENERAL CONTRACTOR: Hochtief and Taylor Woodrow (Joint Venture) MAIN FIGURES: 13,000 Controlled Modulus Columns (CMC), 360-400mm diameter to depths of 4-16m 4,200 Vertical Drains to depths of 10m Project Details The project of Bexhill to Hastings link road consists of [...]

Deep Water Berth at Bootle Docks, Liverpool

OWNER: Peel Ports ENGINEER: AECOM GENERAL CONTRACTOR: BAM and Van Oord MAIN FIGURES: 142 Vibro Stone Columns to depths of 20 metres Project Details BAM and Van Oord were constructing a new deep water berth at Bootle Docks in Liverpool for Peel Ports. This required the reclamation of [...]

Connaught Crossrail Tunnels, London

OWNER: Crossrail ENGINEER: Ove Arup & Partners GENERAL CONTRACTOR: VINCI Construction UK MAIN FIGURES: 3,426 Controlled Modulus Columns (CMC) in 230-360mm diameter to depths between 5-10m 16 SFA micro piles in 450mm diameter to depths of 9.6m 519 CFA piles in 600mm diameter to depths between 6.5-11.5m Project [...]

Industrial Units on the River Stort, Harlow

OWNER: Marbank ENGINEER: Glanville GENERAL CONTRACTOR: Marbank Construction MAIN FIGURES: 3,382 Controlled Modulus Columns (CMC) to depths between 4-8m Project Details Marbank Construction were contracted to build two industrial units (13,000 m2) near the banks of the River Stort. The site had been previously occupied by a much [...]

Queensferry Crossing Bridge, Edinburgh

OWNER: Transport Scotland ENGINEER: Grontmij GENERAL CONTRACTOR: Morrison Construction, Hochtief, Dragados and American Bridge (Joint Venture) MAIN FIGURES: 4,451 Controlled Modulus Columns (CMC) to depths between 11-18m, totalling 52,675 linear metres 62 soil mixing shear walls, representing a surface of 9,200m3 44 Stress Load Tests on single CMCs [...]

Roos Wind Farm, East Yorkshire

OWNER: Renewable Energy Systems Ltd. ENGINEER: N/A GENERAL CONTRACTOR: Forkers Ltd. MAIN FIGURES: 4,911 Controlled Modulus Columns (CMC), 320mm diameter, totalling 55,565 linear metres 18,511 Vertical Drains to an average depth of 7.3 metres Project Details Roos wind farm consists of 9no. wind turbines in the East Yorkshire [...]

Plocks Farm Manufacturing Facility, Bretherton

OWNER: GA Pet Foods ENGINEER: Graham Schofield Associates GENERAL CONTRACTOR: GA Pet Foods MAIN FIGURES: 2,541 Controlled Modulus Columns (CMC) from 7.0-j9.5 metres in length, totalling 19,402 metres Project Details GA Pets food were looking to expand their manufacturing capability by building a new 13,000 m2 facility on [...]

Network Rail Embankment Widening, Avonmouth

OWNER: SITA ENGINEER: Earth Science Partnership GENERAL CONTRACTOR: Balfour Beatty Rail MAIN FIGURES: 1,678 Vertical Drains installed to depths between 7-11 metres Project Details As part of the construction of the Severn Energy Recovery Centre (SERC) for SITA, the existing rail network required upgrading. The existing rail link [...]

Michelin Tyres Factory Extension, Dundee

OWNER: Michelin Tyre Ltd ENGINEER: Cundall Partnership GENERAL CONTRACTOR: Barr Construction MAIN FIGURES: 3,980 Vibro Stone Columns to depths of 5.0 metres Project Details Barr Construction were contracted to build a new factory for Michelin Tyres at their existing facility in Dundee. The new building was to be constructed [...]

Medway Valley Crossing, Holborough

OWNER: Trenport ENGINEER: WSP GENERAL CONTRACTOR: BAM Nuttall MAIN FIGURES: 1,044 Controlled Modulus Columns (CMC) to depths of 11.5-14.5 metres 18,511 Vertical Drains installed to an average depth of 7.3 metres Project Details The works consisted of the construction of a new access road and bridge across the [...]

Lee Valley Ice Centre, Leyton, London

OWNER: Lee Valley Regional Park Authority ENGINEER: Ramboll GENERAL CONTRACTOR: Buckingham Group MAIN FIGURES: 1,234 Controlled Modulus Columns (CMC) installed Project Details Following successful collaboration on previous similar schemes, Buckingham Group approached Menard to find an alternative efficient foundation solution for the redevelopment of the Lee Valley Ice [...]

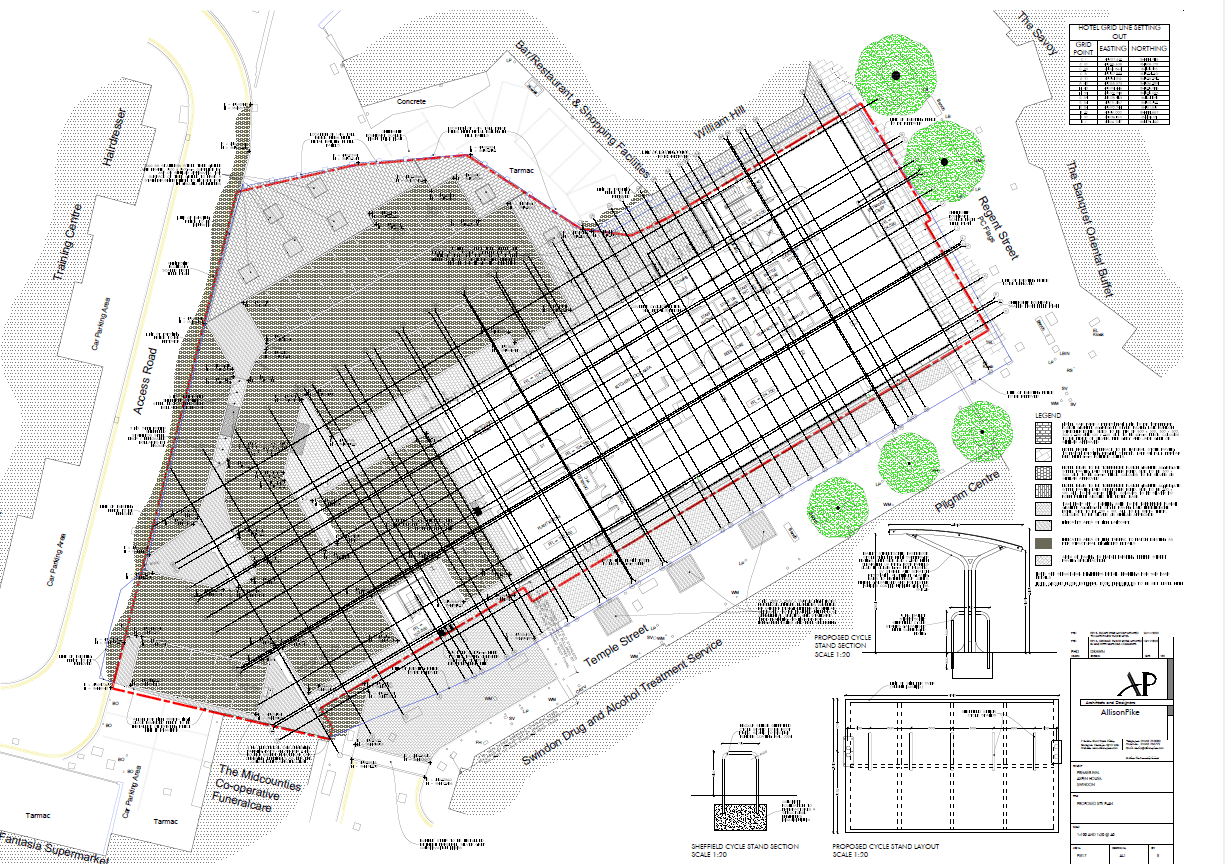

Premier Inn Hotel Development, Swindon

OWNER: Premier Inn Hotels ENGINEER: Simpson Engineering GENERAL CONTRACTOR: Carter Lauren Construction MAIN FIGURES: 700 Vibro Stone Columns (VSC), totalling 2,300 sq/metres Project Details Following detailed technical advice during the design stages concerning the optimum cost-effective ground treatment solution for a proposed 3- 4 storey Premier Inn development [...]

4 Warehouses at Wyvern Retail Park, Derby Triangle

OWNER: St Mowden ENGINEER: Rodgers Leask GENERAL CONTRACTOR: WINVIC MAIN FIGURES: 1,253 units of Dynamic Replacement (DR) Pillars Project Details Winvic approached Menard to find a cost-effective foundation solution for the development of four warehouses at Wyvern retail Park in Derby: Units A1 (4,633 m²), A2 (3,394 m²), [...]

157 Homes on Lily Street Farm Development, Alfreton

OWNER: Peveril Homes ENGINEER: Heathcote & Associates GENERAL CONTRACTOR: Bridge Bank Ltd MAIN FIGURES: 2,004 Controlled Modulus Columns (CMC) installed 4,821 Vibro Stone Columns (VSC) installed Project Details The project consisted in a new residential development comprising 157 plots of single to double storey houses in Alfreton, Derbyshire. [...]

Yiewsley & West Drayton Leisure Centre

OWNER: Hillingdon Council ENGINEER: Buro Happold GENERAL CONTRACTOR: Buckingham Group Contracting MAIN FIGURES: 541 Vibro Stone Columns (VSC) installed Project Details Following successful collaboration on a previous similar scheme, Buckingham Group approached Menard to find an alternative efficient foundation solution for the development of a new leisure complex [...]

118 House Development at Fox Valley, Stocksbridge

OWNER: Stonebridge Homes ENGINEER: Met Engineers GENERAL CONTRACTOR: Henry Boot Construction MAIN FIGURES: 3,413 Vibro Stone Columns, totalling 14,520 linear metres. 37 Plate Load Tests 34 dummy Foundation Load Tests Project Details The development of 118 housing plots was proposed within the Fox Valley area of Stocksbridge, South [...]

Controlled Modulus Columns (CMC)

Where traditional ground improvement techniques may not be suitable, Controlled Modulus Column rigid inclusions (CMCs) provide a fast and economical ground improvement alternative to piling.

Ports & Airports

Port and airport infrastructures are frequently built upon alluvial plains and coastlines. Sites often consist of compressible soils which are saturated, and require ground treatment to accelerate consolidation.

Rail & Road

Menard can provide a range of solutions to meet the varied geotechnical conditions often encountered within the rail & road sector, in order to ensure its long-term reliability.

Process & Energy

The support systems required for energy schemes such as oil, gas, nuclear, windfarm projects are often complex. The most cost-effective foundation solutions often require a combination of ground improvement techniques.

Vibro Stone Columns

Vibro Stone Columns are installed into soft to firm cohesive or loose to medium dense granular natural soils or made ground.

Bi-Modulus Columns

Where CMCs are adopted on sites with near surface granular or mixed soils, the top of the CMC can be replaced with stone aggregate to produce a composite column, known as a Bi-Modulus Column (BMC).

Vibrocompaction

Where sites are underlain by sands and gravels, Vibrocompaction uses our vibrating poker technology to improve the density of these soils commonly on reclaimed land areas.

Dynamic Compaction

Large sites underlain by loose materials can be effectively treated using our Dynamic Compaction, a ground improvement technique that densifies the soil to reduce ground void spaces improving the soil capacity.

Dynamic Replacement

Dynamic Replacement is an adaptation of the Dynamic Compaction process for organic, saturated or weak cohesive soils.

Rapid Impact Compaction (RIC)

The compaction of near surface granular or mixed soils, can be achieved by the introduction of high frequency energy impacts, using our Rapid Impact Compaction technique (RIC).

Vertical Drains and Vacuum Consolidation

Vertical Drains, also known as Prefabricated Vertical Drains or Wick Drains, are made up of a plastic core surrounded by a geotextile that acts as a filter, provide an economical way to accelerate consolidation in saturated soils.

INTERNATIONAL KNOWLEDGE

LOCAL CONTACT

Menard is organised in 7 regions worldwide, our target being to serve the local market in each of those regions through our deep local presence. That local presence is backed by Menard global expertise addressing major projects in those regions together with projects outside of our permanent bases.

We have offices in Southern, Central and Northern England, Northern Ireland and in Scotland. Contact your local office for help and advice on ground improvement for your project.

International Knowledge, Local Contact

Menard is organised in 7 regions worldwide, our target being to serve the local market in each of those regions through our deep local presence. That local presence is backed by Menard global expertise addressing major projects in those regions together with projects outside of our permanent bases.

We have offices in Southern, Central and Northern England, Northern Ireland and in Scotland. Contact your local office for help and advice on ground improvement for your project.

Menard’s international presence

The Menard Group operates throughout the world, with a reputation for quality, innovation and engineered solutions. From design to construction, Menard proposes and implements innovative foundation solutions based on high-performance ground improvement and reinforcement techniques.

Menard’s international presence

The Menard Group operates throughout the world, with a reputation for quality, innovation and engineered solutions. From design to construction, Menard proposes and implements innovative foundation solutions based on high-performance ground improvement and reinforcement techniques.

DOWNLOAD OUR BROCHURE

We view every project as a unique challenge. Our approach is to question the norm and understand what your needs are and where we can add value to your overall project delivery. Our people’s expertise in geotechnics will be used to provide you with the most economical solution that guarantees technical performance.