OWNER:

Ocado

ENGINEER:

EirEng

GENERAL CONTRACTOR:

Glencar Construction

MAIN FIGURES:

606 Controlled Modulus Columns (CMC) installed

Project Details

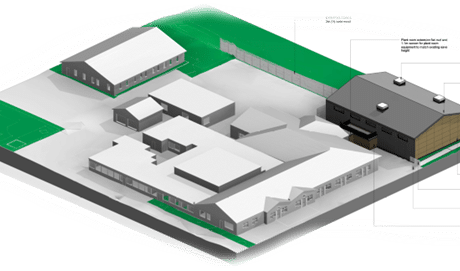

Glencar Construction approached Menard to find a cost-effective foundation solution for the addition of a mezzanine level required by Ocado inside an existing recently-built warehouse at Symmetry Park in Bicester. The mezzanine legs bring significant loads (up to 6,000 kN vertical load) that the existing slab and ground was not able to cater for. A specific solution was therefore required to be able to increase the bearing capacity and ensure that the settlements of the mezzanine legs remain acceptable (specifications of 25 mm total settlements, with 1/500 relative differential settlements). Any solution had to take into account the fact that the works needed to be carried out inside the existing building (confined space), with a clear height of less than 15 m.

Ground Conditions

The available site investigation revealed very homogeneous ground conditions all across the treatment area, with up to 2.5 m of firm clay of the Peterborough Member (CPT cone resistance around 1 MPa) underlain by a 1.5 – 2 m of dense sand (CPT cone resistance above 20 MPa) above very stiff clay.

Solution

Menard designed a solution of Controlled Modulus Columns (CMC) rigid inclusions allowing the construction of conventional pad footings with an enhanced allowable bearing pressure of 350 kPa. The final detailed design comprised more than 600 CMC of diameter 320 mm to be embedded 0.5 m into the dense sand (CMC depth about 2 to 3 m depending on the variations of the embedment layer).

Due to the specific site constraints (limited overhead), Menard used a specially-designed equipment consisting of a multipurpose mast mounted on a excavator. This allowed the site team to complete the CMC installation in less than 2 weeks, the slab being cut at the location of the new pad footings in advance of our works by the Main Contractor. Specific ventilation measures were also provided to ensure the safety of the operatives in such a confined space, whilst rubber mats were used to protect the existing slab.

The works have been verified through a thorough quality control, comprising plate load tests on isolated CMC, compressive strength tests on concrete samples and drilling/concreting logs from the rig computers.