OWNER:

Quorum Estates Ltd

ENGINEER:

Booth King Partnership

GENERAL CONTRACTOR:

Caddick Construction – North West

MAIN FIGURES:

1,160 Controlled Modulus Columns

Project Details

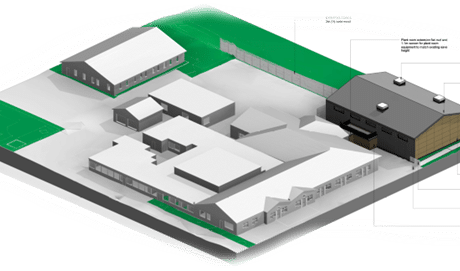

Menard was contacted at an early stage by the Consulting Engineer Booth King Partnership, to assess the feasibility of a site for a ground improvement solution. The development is a brownfield site within an industrial area of South Manchester and comprises 2 no. industrial units including internal office space with haunch heights of up to 10 m. The total footprint area of the two units is c.4,900 m2. A nett bearing pressure of 150 kPa was originally proposed beneath foundations, and a floor slab UDL of 50 kPa.

Ground Conditions

The site is underlain by granular made ground over suspected glacial deposits, comprising variable strength clay onto loose becoming medium dense to dense sand. The boreholes and window samples of the initial site investigation had encountered some horizons of very weak clay which precluded the use of Vibro Stone Columns. Existing buildings occupied the site at this time, including a trailer storage yard and offices. These were demolished shortly afterwards and the site was cleared, ready for the new development.

Solution

Due to the presence of the weak cohesive horizons a Controlled Modulus Column (CMC) solution was proposed. To enable the final detailed design a series of Cone Penetration Tests was undertaken to supplement the original site investigation, thus providing a good understanding of the geotechnical parameters of soils underlying the proposed building footprints. Nearly 1,200 CMCs of diameter c.320 mm were installed to depths of c.3.5 to 7.0 m. Menard was able to propose a total residual settlement of < 25 mm with relative differential settlement limited to 1:500. The installation works were recorded and monitored in real time using Menard’s OMNIBOX™ digital data exchange tool. Thorough verification of the works was undertaken by means of plate load tests, compressive strength tests on concrete samples, and drilling/concreting logs.

Sustainable Development

The Controlled Modulus Column solution enabled the adoption of a 200 kPa SLS nett bearing capacity beneath foundations which was an improvement on the 150 kPa originally proposed by the Consulting Engineer. This resulted in a reduction in the sizes of the foundations, hence contributing to a reduced carbon footprint.