The compaction of near surface granular or mixed soils, can be achieved by the introduction of high frequency energy impacts, using our rapid impact compaction technique (RIC).

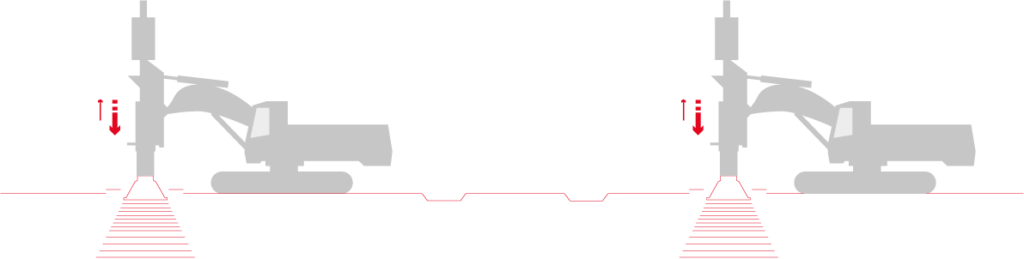

The RIC consist of a compaction foot which is placed on the ground and this is repeatedly struck by a 7-12 tonne hydraulic hammer, resulting in top down compaction of the soils.

Benefits

- Enhanced bearing capacity

- A reduction in the total and differential settlements

- Ground bearing foundation solutions can be adopted reducing the need for reinforced foundations

- The displacement process creates no spoil

Application

- Foundations of low-rise buildings and houses

- Car parks and hard standings

- Reducing contaminated soil volume to avoid cart away costs and fees

- Commercial/industrial foundations and floor slabs with high tolerances

- Infrastructure schemes including embankments, water treatment plants and windfarms

Presentation and key elements

What is Rapid Impact Compaction and when is it suitable?

A high-frequency, controlled energy, soil compaction technique, Rapid Impact Compaction is used to improve the density of surface soil layers to depths of 5 to 7 metres. It is often used due to the low impact on the immediate worksite vicinity, it can densify loose granular soils (sand or gravel) and fill material. Rapid Impact Compaction is commonly adopted on industrial brownfield sites for surface compaction, foundations and floor slab support and waste stabilisation.

Fundamentals of Rapid Impact Compaction

Similar to other compaction and densification techniques, Rapid Impact Compaction is a transmission of energy into a compressible or loose soil layers, to improve its geotechnical properties.

How does Rapid Impact Compaction work?

Firstly, a Rapid Impact Compaction plate is placed on the ground to be treated. Then, a hydraulic hammer (which is generally less than 10 to 15 tonnes in weight) is fitted to an excavator and used to repeatedly transmit compaction energy to the ground.

A safe working distance to sensitive structures can usually be defined as between 8 to 10 metres, and a distance of 5 to 6 metres can usually be adopted for non-sensitive structures. With this working distance employed, noise levels are lower than 90 dBA.