OWNER:

Taylor Wimpey

ENGINEER:

Whitby Bird

GENERAL CONTRACTOR:

Sirius Group

MAIN FIGURES:

8,000 sq/metres Dynamic Replacement (DR)

15,000 sq/metres Dynamic Compaction (DC)

Project Details

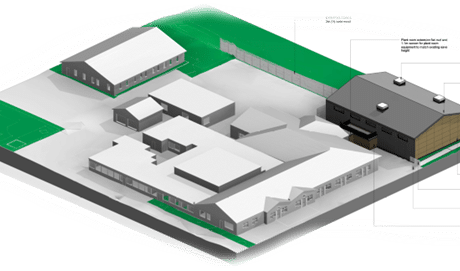

Menard completed Dynamic Compaction/Dynamic Replacement (DC/DR) works beneath 106 housing plots and associated roads, retaining walls and gardens for a new residential development at Clayton Wood Road, Leeds, West Yorkshire. Dynamic Replacement (DR) was used beneath the housing plots (rafts with bearing pressure of 50 kPa) and the retaining walls (bearing pressure of 150 kPa) due to the higher loads to be supported, whilst Dynamic Compaction (DC) was carried out beneath the more lightly loaded roads and gardens.

Ground Conditions

The site lays over a former sandstone quarry that had been infilled with quarry waste fill (mainly silty sand with cobbles and boulders, but sometimes with a more cohesive matrix) and imported fill. The imported fill was found to be highly variable made ground comprising gravels, sand, cobbles of brick clinker, demolition rubble, sandy clay, occasional wood fragments but also organic and putrescible material. Beneath this made ground layer was the sandstone bedrock. The groundwater level was encountered generally within the bedrock, with perched groundwater in some areas.

Solution

Menard proposed to treat the whole site (housing plots, retaining walls, roads and gardens) using the Dynamic Compaction/Dynamic Replacement (DC/DR) techniques in order to increase the bearing capacity of the soil and ensure long term settlements performance (25 mm beneath the housing plots and 50 mm elsewhere). This solution presented significant advantages over a traditional piling scheme: no issues with the obstructions within the made ground, reduced overall costs and significant reduction of carbon footprint of the whole project.

A specific sequence of works had to be devised because of to the numerous different plateau levels with associated retaining walls required on the site because of the topography. An extensive testing regime had been put in place to demonstrate the effectiveness of the DC/DR works for all areas. This comprised Cone Penetration Tests (CPT) prior and after the ground improvement in the made ground, CPT inside the DR pillars, as well as dummy footing tests. Vibration monitoring had also been put in place for the duration of the DC/DR works.

Sustainable Development

The use of Dynamic Compaction/Dynamic Replacement (DC/DR) significantly reduced the carbon footprint of the project as no supply of material was required for DC and only aggregates (no concrete or cement) for DR. In addition, the aggregates were sourced locally, taken directly from the cut areas of the site. DC/DR represents overall a very eco-friendly ground improvement alternative to traditional piling for brownfield remediation.