OWNER:

Bloom Developments

ENGINEER:

Jackson Purdue Lever

GENERAL CONTRACTOR:

TanRo

MAIN FIGURES:

216 Controlled Modulus Columns

Project Details

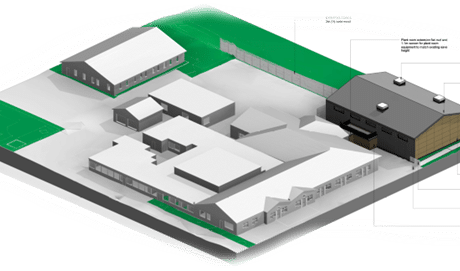

TanRo approached Menard to find a cost-effective alternative foundation solution for a development by Bloom of two industrial units totalling 600 m² of ground floor in a prime location in Hackney Wick, London. The two-storey office and warehouse buildings are designed to a FM2 specification to support a uniformly distributed load of 37.5 kPa, whilst the frame structure brought point loads of up to 2,000 kN SLS.

The site is located in a very constrained environment: it borders on an elevated section of the A12 road (managed by Transport for London – TfL) to the West and an embankment supporting an Overground railway line (managed by Network Rail) to the East, with an extremely tight site access under the A12 overbridge.

Ground Conditions

The initial site investigation revealed relatively homogeneous ground conditions, with about 2 m of made ground underlain by 2 m to 4 m of very soft alluvial clay above loose to dense sands (Taplow Gravel Member), soft to firm clay (London Clay formation) and variable layers of soft clay, dense sand and stiff clay of the Lambeth Group. At the request of Menard, additional CPT have been carried out across the whole site to map more precisely the variations of the different layers and inform the detailed CMC design.

Solution

Menard offered a bespoke solution of Controlled Modulus Columns (CMC) rigid inclusions allowing the construction of conventional shallow foundations. This ground improvement solution brought significant benefits to the overall project compared to a traditional piling scheme, by reducing the embodied carbon footprint, accelerating and simplifying the construction sequence, and reducing costs.

The CMC have been designed to reduce the residual settlements to 25 mm, with relative differential settlements lower than 1/500, and enhance the allowable bearing capacity to 200 kPa beneath the footings. The final detailed design comprised more than 200 CMC taken to depths about 8 to 12 m. The design, carried out in close coordination with the Engineer, included specific analysis to assess the impact of the CMC on the adjacent Network Rail and TfL assets.

The CMC works have been completed on time in a week on site and have been verified through a thorough quality control system. In such a constrained environment, coordination with other trades was paramount and site-specific measures have been implemented to ensure that the works were conducted safely.

Sustainable Development

The use of Controlled Modulus Columns (CMC) instead of deep CFA piles greatly reduced the embodied carbon of the construction, by removing the need for heavy carbon-emitting structures such as pile caps and suspended slabs. Furthermore, the use of a low-strength and low-carbon concrete, with a mix design using a high proportion of GGBS, led to a further reduction of the overall carbon footprint of the project.