OWNER:

Premier Inn Hotels

ENGINEER:

Simpson Engineering

GENERAL CONTRACTOR:

Carter Lauren Construction

MAIN FIGURES:

700 Vibro Stone Columns (VSC), totalling 2,300 sq/metres

Project Details

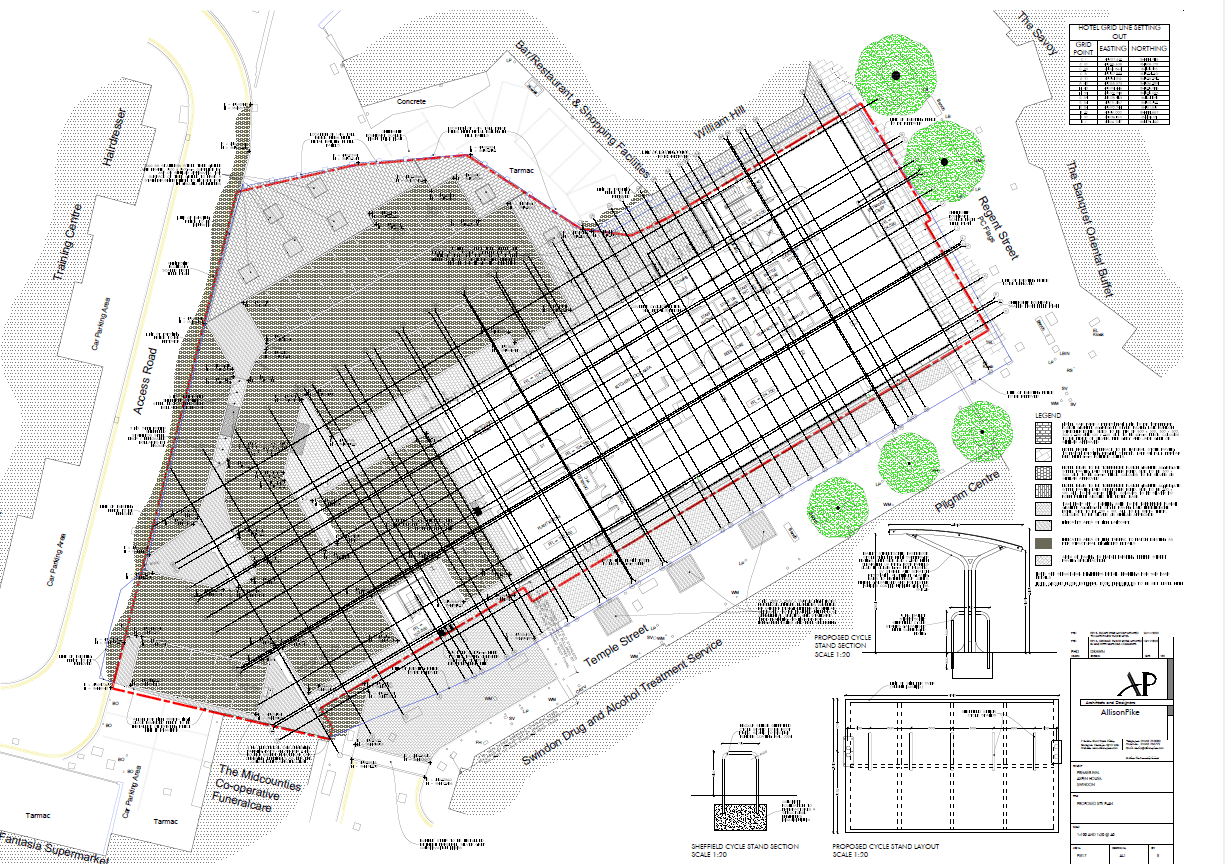

Following detailed technical advice during the design stages concerning the optimum cost-effective ground treatment solution for a proposed 3- 4 storey Premier Inn development between Simpson Engineering and Menard some months before a start on site, Carter Lauren (who were awarded the Main Contract) then approached Menard as the preferred ground treatment Contractor to undertake the installation of Vibro Stone Columns (VSC) in May 2022.

Ground Conditions

Ground conditions on site were split across the building footprint between: a) soils in the intact basement areas consisting of compact crushed brick and concrete backfill onto stiff natural clays, and b) soils outside the basement areas which were soft/firm clayey made ground onto stiff natural clays. The site was set at a platform level of 105 m ie. 300 mm below the FFL of 105.3 m and involved a minor amount of upfilling in the range of 300-400 mm to establish this working platform . This granular upfill also served as the working platform for the VSC and pre-bore rigs.

Solution

In order to enable the construction of regular shallow foundations Vibro Stone Columns (VSC) were chosen to reinforce both the granular made ground inside the basement and the cohesive made ground outside the basement. Due to the variability in the made ground Menard advised designing the strip footings to 200 kPa inside the basement and 165 kPa outside the basement.

The design was based on treating to refusal within the basement area (onto the basement floor slab – which was left in-situ) through the dense granular fill assisted by pre-bore, VSC depths ranged from 2.5 m to 3 m in these areas. Outside the basement treatment was taken into the stiff clays to depths in the range of 4 m to 5 m. Settlements were limited to 25 mm total settlements with relative differential settlement of 1/500 maximum. The final design was about 700 stone columns and 2300 m which amounted to a saving of about 20% in embedded carbon on the project.

The works were completed on schedule using 1 VSC rig and 1 pre-bore rig.