Where traditional ground improvement techniques may not be suitable due to either poor soil strength, high loadings or tight settlement criteria, controlled modulus column rigid inclusions (CMCs) provide a fast and economical ground improvement alternative to piling.

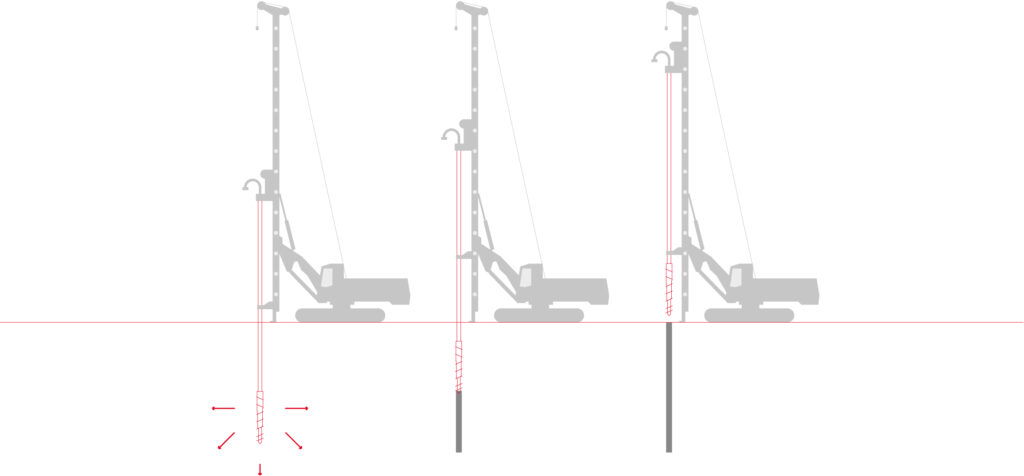

The technique installs low strength concrete columns, 280mm to 500mm in diameter, up to 50m in depth using our displacement tools

Presentation and key elements

Benefits

- Suitable across a range of soil types including soft to very soft organic clays

- Enhanced bearing capacity

- A reduction in the total and differential settlements

- Ground bearing foundation solution utilising a distribution mattress

- The rig working platform can be used as part of the distribution mattress

- No breaking down of CMCs. Trimming is undertaken while the CMCs are still wet

- The vibration free displacement process creates minimal spoil

Applications

- Heavily loaded commercial/industrial floor slabs

- Road and rail embankments

- Silos, tanks and wind turbines

- Residential buildings traditionally founded on driven piles

What are CMC rigid inclusions and why do we use them?

Controlled Modulus Columns (CMC), otherwise known as rigid inclusions, are a ground improvement technique that controls and reduces settlement and increases bearing capacity in soft or loose soils. As an alternative to traditional deep foundation solutions, Controlled Modulus Columns can economically improve the global design of overlying structures.

Fundamentals of CMC rigid inclusions

The reinforcement of the soft or loose soil layers increases the bearing capacity and reduces settlement through using rigid inclusions. The scheme details a load sharing system combining the existing soil capacity and the stiffer rigid inclusions to ensure compliance with project specifications.