Vibro stone columns are installed into soft to firm cohesive or loose to medium dense granular natural soils or made ground.

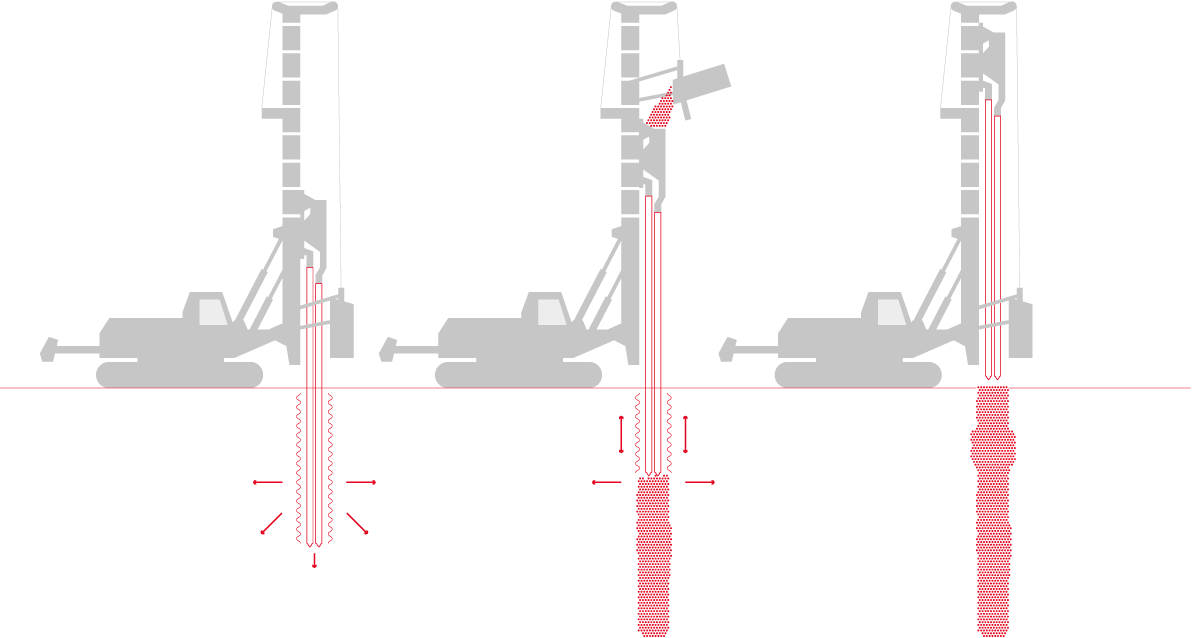

Depending on ground conditions the stone columns can be installed using either our top feed (stable soils) or bottom feed (unstable soils) systems to ensure a continuous dense column from the base of the treatment to the working surface.

Benefits

- Enhanced bearing capacity

- A reduction in the total and differential settlements

- An increase in the permeability, allows acceleration of anticipated settlements

- Ground bearing foundation solutions can be adopted reducing the need for reinforced foundations

- The displacement process creates no spoil

Application

- Foundations of low-rise buildings and houses

- Commercial/industrial foundations and floor slabs with high tolerances

- Infrastructure schemes including embankments, water treatment plants and windfarms

Presentation and key elements

What are stone columns and why do we use them?

Vibro Stone Columns, as with other ground improvement techniques, reduce settlement and increase load-bearing capacity. They increase soil consolidation as a result of the drainage capacity of the granular material within the columns, acting as a pore or water pressure evacuation points. On projects where improving slope stability and preventing liquefaction is essential, Vibro Stone Columns are particularly effective as they increase shear strength within a soil.

Fundamentals of Vibro Stone Columns

Vibro Stone Columns can be made from stone or sand, installed in a grid pattern into soft soils beneath the surface. Otherwise known as aggregate piers, the columns improve soft or loose soils as they create vertical inclusions with high stiffness, shear strength and draining characteristics. Once installed, the ground improvement technique results in an increased bearing capacity, and a reduction of the total and differential settlements.

How are Vibro Stone Columns installed?

A vibrating probe penetrates the soft soils to the necessary depth and to compact the material incorporated. Construction methods include dry and wet, vibrating probes in the top or bottom of the tool or a pendulum or mast-guided system. Methods for incorporating the materials (bottom feed / top feed) can be used in combination to meet the project requirements and specifications.